reduction ratios crushers

reduction ratio of secondary crushers

Crusher Reduction Ratio Mineral Processing Extractive Metallurgy. Jul 2, 2016 ... What is the impact of the Crusher Reduction Ratio on crusher performance. Read More. Introduction to Rock Crushers ELRUS Aggregate Systems. Sep 19, 2012 ... Cone crushers take the material from a jaw crusher and further reduce the material size.

aggregate reduction ratio crushers BINQ Mining

Nov 09, 2012· CONQUIP – Used rock crushers for aggregate and mining. Crusher Terms, crusher types, and reduction ratio Animations of how cone, jaw, and roll crushers work, go here Cone crusher: A crusher that breaks material by . »More detailed

C1554 Cone Crusher Crushing, Screening, Washing ...

The ® Finlay C1554 is the ultimate mobile solution for any aggregates producer or contractor looking for a high output capacity machine that provides large reduction ratios and an excellent cubical shape. This aggressive machine incorporates the proven ® MVP450x cone crusher that can accept an all in feed and features direct variable speed clutch [.]

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

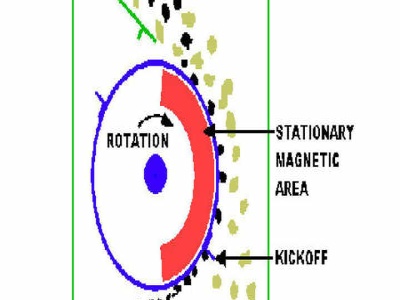

Gyratory Crushing Action. When the mantle moves away and the rock drops down further and subject to additional crushing during the next cycle . Material exits the crusher through the open side setting. Thus, the top size of the product is determined by the open side setting.

reduction ratio crusher

Reduction Ratio For Crushers How To Calculate Reduction Ratio Of Jaw Crusher reduction ratio main use; jaw crushers the dodge jaw crusher has a variable feed area and a fixed ball mill for ...

Reduction Ratio Range For Mining Jaw Crusher

High Reduction Ratio Crusher 911Metallurgist. 10″ x 16″ High Reduction Ratio Jaw Crusher 911MPEJC400 Jaw Crushers for Coarse Primary Crushing and Mid Range Primary Crushing. This TPH jaw crusher is equipped with a 20 HP motor and a 7″ X 14″ jaw cavity that will produce a discharge crushed product of under . 10mm.

Crushing 101 | Masaba

Jaw Crusher. 8:1 maximum reduction ratio for compression crushing, this is normally used as a primary crusher. Jaws perform well in many materials. Yields low wear cost per ton in hard abrasive deposits, minimal fines but produces little finished (under 1") product which places more load on the crushers downstream in the circuit.

Jaw Crusher ScienceDirect

Taggart expressed the relationship between crusher capacity and reduction ratio in terms of a reduction ton or tonne, Q R defined as () Q R = Q T ⋅ R 80 where Q T is the capacity in terms of actual tonnage crushed per hour. The quantity of feed actually crushed is determined by subtracting the feed undersize from the total quantity of feed.

How it Works: Crushers, Grinding Mills and Pulverizers ...

Crusher buckets are excavator attachments that contain two jaws, one fixed and one that moves back and forth, much like a jaw crusher. Grinding Mills and Pulverizers. Grinding mills and pulverizers are the second level of material reduction equipment after crushers.

Gundlach's 1000 Series has Roll Crushers

High Ratio of Reduction To accommodate a variety of crushing applications, the crusher achieves reduction ratios up to 16:1. Compact Design Compared to similar equipment, AccuGrind has a much smaller footprint. Its base is less than square meters, making it well suited for smaller space applications. Ideal for Sampling

sand and aggregates, crushing, maximum yield The Weir Group

May 23, 2017· A "best practice" strategy is to accept higher reduction ratio in secondary crushing so that it can be lowered in tertiary crushing. Another strategy to consider is to operate both the secondary crusher and the tertiary crusher in closed circuit with a wider closed side setting and an increased recirculation load from the sizing screens.

Stationary HSI impact crushers — Sandvik Mining and Rock ...

High reduction ratios The perfect crusher for Primary (feed sizes up to 900 mm) and Secondary crushing for the limestone, recycling and cement industries. Achieve 2 stage plants instead of the usual 3 stage plants in aggregate production.

Raptor® Cone Crushers Smart cone crushers with advanced ...

Maximum reduction ratios With a combination of variable speed and large throw, Raptor cone crushers provide high reduction ratios. Because of their efficient crushing action, the crushers have a large power utilisation per cone diameter. The high cavity density improves interparticular

How To Calculate Jaw Crusher Reduction

Reduction Ratio Of A Crushers greenrevolutionorgin. how to calculate reduction ratio of jaw crusher Zenith crushing equipment is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and, Read more reduction ratio in stone crusher Crushing Equipment .

Reduction ratio of jaw crusher Henan Mining Machinery Co ...

TYPES OF CRUSHERS As stone passes through a crusher the reduction in size may be expressed as reduction ratio The reduction ratio is the ratio of crusher feed size to product size The sizes are usually defined as the 80 passing size of the cumulative size distribution For jaw crusher the ratio can be estimated by the gape CHAPTER 14.

Jaw Crusher ScienceDirect

In order to calculate the capacity of crushers, Taggart considered the size reduction, R 80, as the reduction ratio of the 80% passing size of the feed, F 80, and product, P 80. This may be written as () Reduction ratio, R 80 = F 80 / P 80

reduction ratio of secondary crushers

The reduction ratio for jaw crushers range from 3/1 to 5/1. Jaw crushers... Chat Now. Secondary Impact Crushers Stone Granite Crushing Equipment ... The fieldproven, Stedman Grand Slam secondary impactor will give you years ... High reduction ratios up to 30:1; Cubical gravel crusher .

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT .

c) Fine crushers Fine crushers have relatively small openings and are used to crush the feed material into more uniform and finer product. Example Gravity stamp. Table 1. Comparison of different types of crushers [6] Type Hardness (input material) Abrasion limit Reduction ratio Use Jaw crusher Soft very hard No limit 3:1 to 6:1

reduction ratio in jaw crusher

Size reduction control Crushing of ore and minerals All crushers have a limited reduction ratio meaning that size reduction will take place in ... For harder feed there is a choice between a gyratory or a jaw crusher.

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open side set (OSS) is specified.

Latest Posts

- كسارة كسارة الذهب

- تعليقات سحق الأساسية

- عملية تعدين الفحم في الجزائر

- محجر الحجر محاكاة كاملة المحمولة

- ريموند مطحنة للبيع الجزائر

- كسارات الصابورة مستعملة

- خام المنغنيز المورد كسارة مخروط

- سعر آلة صنع مسحوق المنظفات

- مورد معدات مصانع الاسمنت في اليابان

- سحق الجرانيت مصنعين

- كسارات الحصى وغسل الرمل

- الياقوت النباتية لغسل المحمول

- حار بيع سلسلة حماية الإطارات للبيع

- مصنع كسارة في ناميبيا

- سعر كسارة متنقلة خام تاكونيت

- hydraulique concasseur de pierre opération australie

- nouvelle decision de la machine produit bas prix a delhi

- crushers in turkeygarantee makina crusher in turky

- graphique axial crusher

- prix keestrack machoire crucher

- mélange prix d usine de ciment au pakistan

- usines de textile bancaires propres a vendre au pakistan

- location écran concasseur pty ltd

- contuctuion et l application de piédestal moulin

- dolomite concasseur à petite échelle

- concasseur mobile sbm pour le cuivre

- cours du pharmacie le broyage

- sable le prix de la machine de production

- métamorphiques et roches ignées

- concassage de minerai de plomb